Structural Natural Frequency Analysis

November 28, 2017

Structural natural frequency, also referred to as reed critical frequency (RCF), is the single greatest factor which prevents excessive vibration in a vertically suspended pump. Operating close to or on a structural natural frequency will result in high vibration levels. This high vibration level can result in premature or catastrophic failure of the equipment.

Key Terms:

- Motor RCF Data

- Operating Speed Range

- Separation Margin

Motor RCF Data is information provided by the motor manufacturer. This data includes the center of gravity, deflection at the center of gravity, the unit weight and the reed critical frequency.

The Operating Speed Range is the speed range at which the pump will operate. A constant speed application will have a single operating speed range for the pump. A pump operating on a VFD will have a speed range typically from 70 -100% of full load speed. If sufficient system data is provided, the speed range will be determined based on that system data and the minimum flow of the pump.

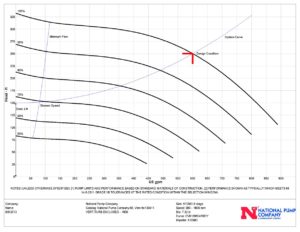

Figure: System Data w/ Pump Data – Speed Range 69% to 100%

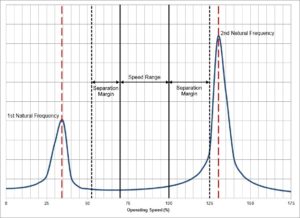

Separation Margin is the percentage of the operating speed which the natural frequencis are above or below. The analysis margin is greater than the field margin. This increase is to cover uncertainties in the analysis and data. Acceptance field margins are +/-10%. Acceptable analysis margins vary based on the analysis method.

Figure: Natural Frequency Plot w/ +/-25% Separation Margin & 70 – 100% Speed Range  Analysis on new equipment is the easiest and most cost effective way to prevent this type of issue. The Hydraulic Institute (HI) has developed a Dynamics of Pumping Machinery (9.6.8) standard which provides guidance on this type of analysis with several levels of analysis.

Analysis on new equipment is the easiest and most cost effective way to prevent this type of issue. The Hydraulic Institute (HI) has developed a Dynamics of Pumping Machinery (9.6.8) standard which provides guidance on this type of analysis with several levels of analysis.

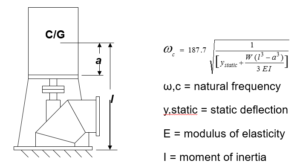

A level 1 analysis is a basic handbook calculation. National Pump Company performs a level 1 analysis at a minimum on all fabricated discharge heads. The calculation is based on a cantilever spring supporting a mass for the first mode natural frequencies. The discharge head acts as the spring which the stiffness is calculated for while the motor acts at the mass. The second mode natural frequencies are estimated as being four times the first modes. An analysis margin of +35%/-25% is used. This margin and the ratio of the 2nd modes to the 1st modes was determined from experience using this calculation method in conjunction with more complicated analysis and field data to ensure no issues result.

Recommended text from HI 9.6.8 Appendix E

To determine the potential for a critical structural natural frequency occurring within the normal operating speed range of the pump, a level 1 structural dynamic analysis shall be performed of the vertical pump structure in accordance with ANSI/HI 9.6.8 Rotodynamic Pumps Guideline for Dynamics of Pumping Machinery, Table 9.6.8.4. The structural reed critical frequency (RCF) calculation shall be performed in accordance with Section 9.6.8.5.7 and Appendix C. The minimum frequency separation margin obtained by analysis shall be ± _____ (to be completed by specifier).

National Pump Company would recommend a margin no less than +/-25% for a level 1 analysis.

Figure: Basics of a Level 1 Analysis

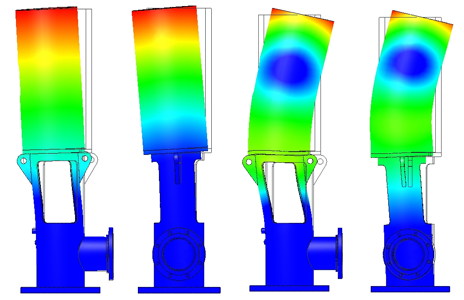

A level 2 analysis is a finite element analysis (FEA). National Pump Company performs a level 2 analysis anytime specified or when a level 1 analysis does not find a suitable solution. This analysis uses a 3D model of the discharge head along with a simplified motor which matches the manufactures specified RCF data. An analysis margin of +/-20% is used. This margin is due to the high accuracy of the analysis results compared to field data.

Recommended text from HI 9.6.8 Appendix E

To determine the potential for a critical structural natural frequency occurring within the normal operating speed range of the pump, a level 2 structural dynamic analysis shall be performed in accordance with ANSI/HI 9.6.8 Rotodynamic Pumps Guideline for Dynamics of Pumping Machinery, Table 9.6.8.4. The pump structure shall be subject to a natural frequency analysis (modal FEA) in accordance with Section 9.6.8.6.2.3.3. The minimum frequency separation margin obtained by analysis shall be ± _____ (to be completed by specifier).

National Pump Company would recommend a margin no less than +/-20% for a level 2 analysis and does not recommend a margin greater than +/-25%.

Figure: Mode Shapes from Level 2 Analysis (left to right: 1st Mode Inline, 1st Mode Transverse, 2nd Mode Inline, 2nd Mode Transverse)

A level 3 analysis is a more complicated finite element analysis (FEA) which requires consideration of the foundation and be subjected to a forced response analysis. This analysis is outside the analysis capabilities of National Pump Company and would require outsourcing if required. Consideration of the foundation is important when the foundation does not meet the as definition of rigid per HI 9.6.8. Simple foundation considerations can be applied to a level 2 analysis.

National Pump Company does not perform any analysis on cast discharge heads. These discharge heads have extensive operation history, showing suitability of various models and motor combinations operating at constant speeds. These heads can be used in variable frequency applications, however, National Pump Company only guarantees the performance at full load speed. If a structural natural frequency is identified at a lower speed, a lock out range must be used. If a lock out range is not acceptable, a fabricated discharge head is required. The fabricated discharge head is then analyzed and designed specifically to meet the required speed range.